Ceramic High Flow Separator (CHFS)

Developed for treatment of produced water in the oil & gas industry, CHFS is a new ceramic membrane microfiltration process originally developed with the support of the UK Government.

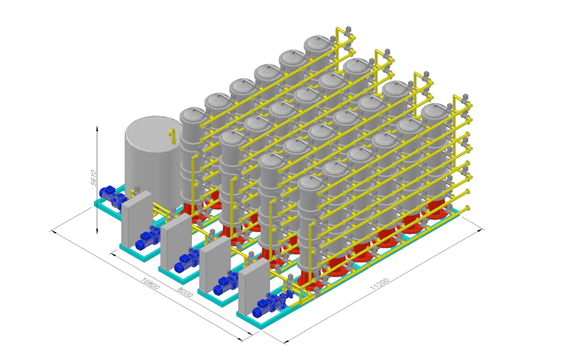

CHFS removes suspended oil and solid particles from high flow rate industrial effluent. CHFS is designed for flow rates from 10 m³/h to over of 5,000 m³/hour, >reducing the dispersed oil level to less than 10mg/l and suspended solids to less than 5mg/l.

CHFS is a cost effective process enabling operators to meet the most stringent current global produced water discharge limits and the envisaged OSPAR Commission regulations.

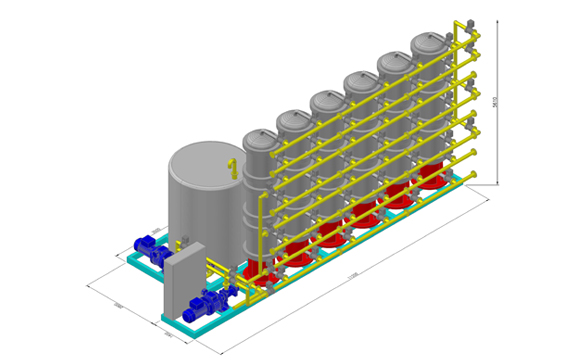

CHFS is modular and suited for both onshore and offshore production wells. The plant is compact, produces no secondary wastes for disposal and is easily incorporated into a production process whether as a retrofit or new build.